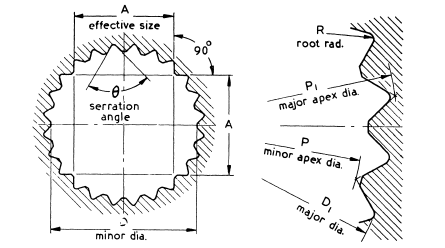

Internal splines are formed by broaching or by a gear shaper. The external spline can be formed either by hobbing or by a gear shaper. Involute splines are the predominant form bacause they are stronger than straight sided splinesĪnd are easier to cut and the fit.

It is emphasised that the splines identified are side fit with the centering based on the sides of the splines In accordance with BS ISO 4156:2005-1 Straight cylindrical involute splines. The notes and tables below relate to straight cylindrical involute splines Using the relevant standards or quality reference sources. The information on this page is not detailed and has been obtained by reference to The product has a keen market price, fast delivery and ISO9001 assurance to give the product a competitive edge.It is also possible to become a BSI member and obtain copies of The splined shafts can also be complimented by a range of matched phosphor bronze flange nuts’ which are supplied complete with PCD arranged attachment holes. Standard lengths of 250,500,1000,20mm are available from stock. A full range of flanged steel or bronze sleeves are available to compliment the splines.

Abssac was successful in being able to replicate the part and deliver the new part ready to fit into the repaired machine.Īs standard splined shaft are available from 14mm to 54mm in diameter with either 6 or 8 spline formats. The only information available was to be gathered from the broken and distorted sample sent to us after a catastrophic failure at the paper mill. Manufactured from EN24T steel the customer did not have any technical drawings from which we could quote from.

Measuring a massive 150mm in diameter, with 8 splines along its 2 metres length and weighing in at 250kg !. Machined from high grade EN8 steel in diameters of 14mm to 54mm as standard and supplied in lengths up to 3 metres enables us to supply into the most high load and long life expectancy linear applications.Ībssac has recently supplied one of the largest splined shafts to date.

0 kommentar(er)

0 kommentar(er)